Technologies Used

- ROS

- Python

- PID Controller

- Bayesian Localization

- Raspberry Pi

Github Repository: Delivery-Robot

Introduction

We design the control to simulate a Mail Delivery Robot, as the final project of our robotics class. We are given a topological map of an office track, and enable a robot to stop at the instructed offices by implementing both Bayesian Localization and a PID controller. The offices, numbered from 1 to 12 are unique but their color (sensor reading) is not. They are connected by a black line that the robot follows.

Topological map

Personal Contributions

- Design of the Bayesian Localization algorithm

- Design and tuning of the PID controller

- Debugging and integration of the different components

Video Demonstration

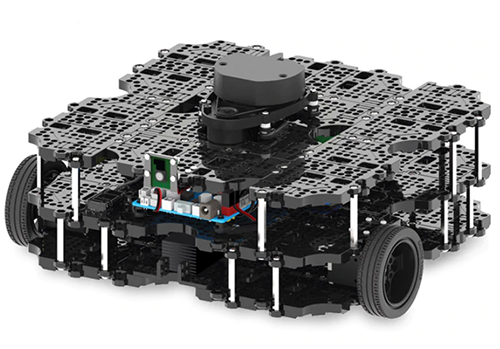

Robot Platform

We worked with a TurtleBot3 Waffle Pi equipped with the Pi Camera, pointed downward to examine the area underneath the robot. The camera is useful when mounted this way as it can be used for line following and floor color detection. The different sensors (Camera and motors) communicated with each other through a ROS infrastructure that was provided to us. We were provided with the code for perception and data extrapolation from the Pi camera.

Solution Strategy

Line following

We use the Pi camera to detect the current color the robot is on. If the color detected is black, we expect it to be on the line, otherwise, we assume the robot to be in an office.

To follow the line we use the camera to determine whether the line is centered in the frame. If the line is not, we assume that the robot’s trajectory needs to be corrected and we use a PID controller to perform the correction. If properly tuned, we assume the PID controller to always maintain the robot centered on the line.

If the color detected by the camera is not black, we assume the robot has reached an office. As the offices can be crossed by traveling forward in a straight manner, we decided to turn off the PID in these areas to avoid twitching. The offices are uniformly colored and span the whole field of view of the camera. It is therefore impossible for the robot to correct its trajectory given the image shown. Leaving the PID controller on when the robot is in an office, would imply uncontrollable path deviation. Turning off the PID controller in the offices, implies blindly moving forward for some time. If our PID controller is properly tuned, the robot will be centered on the black line before entering an office, and it will therefore find the black line again after exiting the office, as the black line doesn’t change direction within the office span.

Robot localization

For Robot localization we use Bayesian localization. Once we encounter an office we use the Bayesian model to keep track of the previous colors and predict the current office given the current color measured. We initialize the initial position to be uniformly probable across all the states since the robot can start from any location. We expect the model to converge to the right position after some offices have been visited. We therefore keep looping around the track until the model becomes confident enough in its current state.

Comments on implementation

Our PID controller was tested in previous labs so we expect it to be straightforward to implement. We will first implement our Bayesian model on its own, and ensure its functioning by simulating a virtual track. This will allow us to debug it without having to test it on the robot. We expect color detection to be the harder part of the lab. This is the solution we identified. The color detected by the camera at any point is one of the following: black, blue, green, yellow or orange. We will therefore provide the RGB values of such colors to our robot. We calibrate the RGB values corresponding to the colors of the offices based on the mean of several observations taken form the track. When we run the robot we will then compare the colour measured by the robot to the provided ones, and determine which on it is the most similar to. We have different ideas to determine such similarity. We will converge on the best one in later sections. We will test

- Norm of Differences: Take the difference between the measured value and one of the provided values, and calculate the norm of the final vector. The measured value will be the one with the smallest norm.

- Cosine Similarity: Determine the angle between the measured rgb value and the provided values. The measured value will be the one with the smallest angle.

Methods

Bayesian Localization

We implemented the code by following the theory behind Bayesian localization. When testing it on the robot, we noticed that no matter the starting position, it took the same number of offices visited to confidently converge to the correct one. We therefore decided to implement a threshold: our robot would ”be certain” of its localization only after exploring three offices. This simplified the logic of our code while still reducing the risk of stopping at the wrong office.

Improving color detection

HSV format

We noticed that the RGB values of the colors were very close to each other, and both methods listed above failed to determine similar colors consistently. We therefore switched to HSV values as they allowed more distinction between colors than RGB. Out of the options described earlier, we chose cosine similarity as it provided more accurate results.

Robot add-ons

We tried other approaches to reduce the error in color detection such as using a physical cone made of paper to have constant lighting, or using a portable light placed on top of the camera. Both of those approaches made color detection slightly worse. The failure of the cone to produce accurate measurements was likely caused by the fact that it appeared in the camera field of view and it distorted the values of the color detected. The portable light made the floor too shiny and negatively impacted the color detected as well.

Color Filtering

When entering a new office, we noticed a transient period during which multiple colors were detected one after the other. We therefore created a list (COLOR-LIST) containing the last K detected colors measured by the camera. When a new color was detected, we appended it to the end of the list and popped the first element. We only changed the current color variable, indicating the color the robot thought it was on, when all the colors in that list were the same. For example, if the robot was on the line and it is now starting to see an orange office. COLOR-LIST, if K = 5, will probably look like [”black, ”black, ”yellow”, ”orange”, ”orange”]. In this case current color is still ”black”. Only when COLOR-LIST = [”orange”, ”orange”,”orange”, ”orange”,”orange”] the current color will be equal to ”orange”. Even after this modification, our robot struggled to detect the black line after specific colors. For example, after crossing a yellow office, our robot tent to confuse the line with blue. Therefore, we hard-coded the fact that after visiting an office, the next color measured had to be black, and we disregarded all other measurements.

PID Control Activation

The introduction of color filtering introduced some problems in our PID system as it was disengaging too late: when entering the office, the robot would twitch. To fix this issue, we stopped the PID controller when at least 27% of the values contained in COLOR-LIST were not black (we found this value through trial and error). Similarly, we wanted to start the PID at the right time after leaving an office so that if the robot deviated while moving across the office, it could be corrected before it was too late. We looked at the mean index of ”black” labels in the list. If the mean was toward the end of the list, it meant that we were getting new black measurements, i.e. that the robot was leaving the office, so we turned on the PID.

Performance Analysis

Our Bayesian localization code successfully converged after 3 offices were visited and our robot was able to detect the office color with 100% accuracy. The following graphs show a sample robot prediction when it starts at office 9. The initial distribution is uniform. The robot measures orange then yellow. It converges to office 10 as {9,10} is the only sequence containing orange then yellow in the topological map (See introduction).

We only noticed some small problems with our PID controller and the color orange. On orange officies, the robot would not turn of PID in time in 40% of the cases. We did not have time to debug this last problem, although we hypothesize that something might be missing from our PID controller activation logic.

Future Improvements

In terms of hardware, a better camera (higher resolution) can improve both PID control and color detection. Fusing the information from multiple cameras could also decrease the error. Another improvement for color detection is the use a Decision-based tree model to assign a color based on the sensor measurement. It would be more resilient against changes in lighting and color shade. It would also give insight into why a color is selected instead of another one - by using metrics such as the SHAP values - which could help to build a better test setup. We noticed that color detection is sensitive to lighting conditions (such as a person moving above the robot), and abrupt changes can cause errors. To fix this issue, we could use a physical cone around the camera, combined with a portable light, and modify the algorithm that measures the color to only measure a subset of the entire image (where we don’t see the cone).

Conclusion

Altogether, this proof-of-concept demonstration was an opportunity for us to deepen our understanding of Bayesian localization while strengthening our skills in prototyping and debugging, all of which are essential to becoming a seasoned roboticist. A key idea that we learned is to build incrementally small components that fit together. We could have tried to build the entire project from the start, but having built and tested each element separately - the PID control, color detection, and bayesian localization - allowed us to pinpoint issues and make steady progress, which are important in terms of efficiency.